Gallery & Case Studies

The Vaults, W1

Details

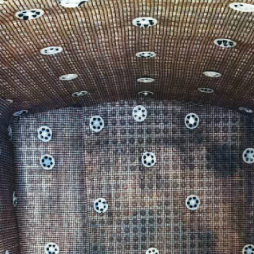

Classic under pavement vaults are commonly found in cities across the United Kingdom.

Historically, in older properties, vaults were used as coal cellars and were not designed for modern living. Basement vaults can extend under the pavement, even as far as roadways.

Basement vaults can incur water ingress/rising and penetrating damp/and can even be prone to flooding. Any structure built below ground, is particularly susceptible to water penetration. This type of moisture ingress is forced through the walls by hydrostatic pressure, which in turn saturates internal wall surfaces.

Basement vaults can easily be retrofitted to be a useful space, such as a utility room, storage space or workshop.

Delta Registered Installers, Renderseal Ltd were employed by the property owners to provide a waterproofing solution to two damp under front pavement vaults that the clients sought to upgraded to use as a plant room for boilers and ancillary

equipment in W1.

During initial on-site inspections, it was evident that the vaults had not previously been waterproofed. The structure was listed, so would require a sympathetic solution. When designing a waterproofing solution for a historic structure, additional consideration at the design stage is required to maintain the structural integrity of the structure or building. The waterproofing design should offer sympathetic installation.

Methodology

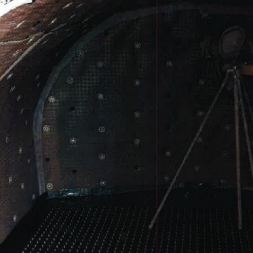

The client sought to use these vaults as a plant room for boilers and ancillary equipment. Renderseal recommended installing Delta PT membrane to the walls and Delta MS20 to the floors with both having a render/ screed applied to the membrane with drainage channels running to a suitable point of discharge.

For this project, a specialist waterproofing system would be required to eliminate the long-term threat of water ingress, a Delta System with its ‘air gap’ technology was the perfect

solution.

A Delta System is a fully reversible system, therefore would not alter the fabric of the listed building. The floor levels throughout varied significantly, so prior to the installation of the Delta system, Renderseal were required to dig down the floors approx. 150mm and relay a new slab incorporating channels.

Renderseal applied Koster Polysil TG 500 an anti-lime inhibitor to the newly poured concrete. Drainage channels were installed in the rebates formed in the new slab, along with flushing points. Followed by the installation of 20mm Delta MS 20 to all the floor areas.

Renderseal installed drainage pipes from the perimeter drainage channel into the manhole with wet trap and nonreturn valves in the manhole. The client wanted a ground drainage system and did not want a sump with pumped system requiring further excavation.

Delta 8mm PT cavity drain membrane was installed to walls and soffits of the vaults and toilet area. Once the system was installed, it was fully tested before the York Stone was relied.

The client required various fixing points for plant, door frames etc so Renderseal used brick plugs with Delta rope in these areas and PT plugs in other areas.

Once installation of the membranes was complete, Renderseal applied nominal 15mm SBR modified render to the Delta PT and 65mm builders’ screed over the MS20.

Results

Renderseal Ltd has provided the clients with dry, commercial and modern plant room which will remain fully protected against the threat of water and damp

ingress. The clients were delighted with the results and were supplied with a 10-year company guarantee.